适用于在土壤/岩石地面条件下工作的推土机。

规格见下表

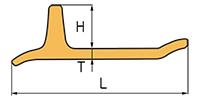

| 序号 | 牌号 | 米重(kg/m) | 规格 (mm) |

| 节距 | 齿高H | 板宽L | 板厚T |

| 1 | S106 | 19.62 | 106 | 35 | 135 | 7 |

| 2 | S125 | 10.85 | 125 | 35 | 140 | 7.5 |

| 3 | S135 | 11.10 | 135 | 38.5 | 150 | 7 |

| 4 | S139 | 14.27 | 139 | 42.5 | 159 | 8.5 |

| 5 | S140 | 16.44 | 140 | 47 | 182.5 | 8.5 |

| 6 | S154 | 19.29 | 154 | 47 | 182.5 | 10 |

| 7 | S154A | 19.70 | 154 | 49 | 182 | 9.5 |

| 8 | S154B | 16.60 | 154 | 47 | 182.5 | 8.5 |

| 9 | S156 | 18.06 | 156 | 47 | 180 | 9 |

| 10 | S159 | 22.01 | 159 | 52.3 | 193 | 11.2 |

| 11 | S159.8 | 19.31 | 159.8 | 49 | 181 | 9.5 |

| 12 | S160 | 21.60 | 160 | 47 | 202.5 | 11 |

| 13 | S165.9 | 19.37 | 165.9 | 62.7 | 179 | 9.1 |

| 14 | S170 | 23.72 | 170 | 57.2 | 197 | 11.5 |

| 15 | S170A | 25.60 | 170 | 57.2 | 197 | 12.7 |

| 16 | S170.5 | 25.19 | 170.5 | 55 | 199 | 12 |

| 17 | S171 | 26.10 | 171 | 50 | 199.6 | 12 |

| 18 | S171A | 22.00 | 171 | 47 | 202.5 | 11 |

| 19 | S171.5 | 21.49 | 171.5 | 47 | 200 | 11 |

| 20 | S190 | 29.80 | 190 | 57 | 225 | 13 |

| 21 | S190A | 28.47 | 190 | 50 | 215 | 12.5 |

| 22 | S196.2 | 32.50 | 196.2 | 58.7 | 237 | 13.8 |

| 23 | S203 | 32.00 | 203 | 65 | 237.5 | 13 |

| 24 | S203A | 30.76(31.1)/35.4 | 203 | 65 | 232.5 | 12/14.3 |

| 25 | S203B | 35.25 | 203 | 60 | 238 | 14 |

| 26 | S203C | 40.20 | 203 | 75 | 243.5 | 15 |

| 27 | S203D | 42.74 | 203 | 65 | 242.5 | 13 |

| 28 | S203.2 | 31.04 | 203.2 | 65 | 232 | 12 |

| 29 | S203.2A | 38.76 | 203.2 | 71.5 | 245 | 14.7 |

| 30 | S210.3 | 44.67 | 210.3 | 71.4 | 248 | 15 |

| 31 | S210.3A | 48.47 | 210.3 | 71.4 | 248 | 16.67 |

| 32 | S215.9 | 37.29 | 215.9 | 66.5 | 249 | 13.5 |

| 33 | S215.9A | 41.84 | 215.9 | 66.5 | 249 | 16 |

| 34 | S216 | 37.40 | 216 | 70 | 247.5 | 14.2 |

| 35 | S216A | 40.80 | 216 | 72 | 252.25 | 14.3 |

| 36 | S216B | 49.38 | 216 | 82 | 256.5 | 17 |

| 37 | S216C | 40.88 | 216 | 65 | 250 | 14.3 |

| 38 | S216D | 54.19 | 216 | 84 | 242.5 | 19 |

| 39 | S216E | 44.6/48.4 | 216 | 70.5 | 249 | 15/17 |

| 40 | S216F | 37.80 | 216 | 71.4 | 249.4 | 14.2 |

| 41 | S216G | 40.80 | 216 | 72 | 252.25 | 14.3 |

| 42 | S216H | 46.60 | 216 | 71.5 | 240.5 | 17 |

| 43 | S228.6 | 50.60 | 228.6 | 80 | 268 | 17 |

| 44 | S228.6A | 56.50 | 228.6 | 77.5 | 261 | 19 |

| 45 | S228.6B | 57.29 | 228.6 | 77.8 | 263 | 19.1 |

| 46 | S228.6C | 70.58 | 228.6 | 93 | 263 | 23 |

| 47 | S228.6D | 50.26 | 228.6 | 80 | 268 | 17 |

| 48 | S228.6E | 59.25 | 228.6 | 80 | 268 | 19 |

| 49 | S228.6F | 48.30 | 228.6 | 76.5 | 276 | 17.5 |

| 50 | S240 | 64.59 | 240 | 84 | 285 | 20(22) |

| 51 | S250.5 | 64.31 | 250.5 | 79 | 289 | 19 |

| 52 | S250.5A | 54.80 | 250.5 | 76 | 292 | 17 |

| 53 | S260.4 | 74.93 | 260.4 | 89.7 | 303 | 20.6 |

| 54 | S260.4A | 77.51 | 260.4 | 88 | 304 | 22 |

| 55 | S260.4B | 83.71 | 260.4 | 101 | 298 | 22.5 |

| 56 | S280 | 83.81 | 280 | 93 | 322 | 23 |

| 57 | S317.5 | 103.00 | 317.5 | 102 | 369 | 25 |

| 58 | S317.5A | 118.00 | 317.5 | 103 | 366 | 28 |

化学成分

| 牌号 | 化学成分(%) |

|

| C | Si | Mn | P | S | Cr | Ni | Cu | B | Ti | Als |

| 23MnBM | 0.21~0.26 | 0.15~0.30 | 0.80~1.10 | ≤ | ≤ | 0.10~0.20 | ≤ | ≤ | 0.0005~0.0030 | 0.01~0.05 | 0.01~0.07 |

| 0.03 | 0.015 | 0.25 | 0.25 |

| 25MnBM | 0.23~0.28 | 0.15~0.30 | 0.80~1.10 | ≤ | ≤ | 0.10~0.20 | ≤ | ≤ | 0.0005~0.0030 | 0.01~0.05 | 0.01~0.07 |

| 0.03 | 0.015 | 0.25 | 0.25 |

| 25CrMnBM | 0.23~0.28 | 0.17~0.37 | 1.10~1.40 | ≤0.030 | ≤0.020 | 0.30~0.50 | ≤0.20 | ≤0.25 | 0.015~0.065 | 0.0005~0.0035 | 0.030~0.065 |

|

淬透性

牌号

| 距离(mm) |

J1.5 | J11 | J13 | J25 |

25MnBM | 42-49 | 28-38 | -- | -- |

25CrMnBM | 46-52 | -- | ≥35 | ≤35 |

淬透性检验按GB/T225执行,正火温度900±10℃,淬火温度870±5℃。

试验方法

| 序号 | 检验项目 | 取样数量/个 | 取样方法 | 试验方法 |

| 1 | 化学成分 | 1/炉 | GB/T20066 | GB/T223 GB/T4336 |

| 2 | 低倍组织 | 1/炉 | 任意流。浇次第一炉取头坯头部,浇次末炉取尾坯尾部。 | GB/T226 YB/T153 |

| 3 | 非金属夹杂物 | 1/炉 | 任一支钢材 | GB/T 10561 |

| 4 | 淬透性 | 1/炉 | 任一支钢材 | GB/T 225 |

| 5 | 晶粒度 | 1/炉 | 任一支钢材 | GB/T6394 |

| 6 | 尺寸 | 逐支 | 整根 | 卡尺 |

| 7 | 表面质量 | 逐支 | 整根 | 目视 |